氮碳氧复合处理

各类模具、机械零件的渗氮处理及后氧化处理,可在提高耐磨性、疲劳强度的同时,使其具备均匀一致的黑色外观及超强的抗锈蚀能力。

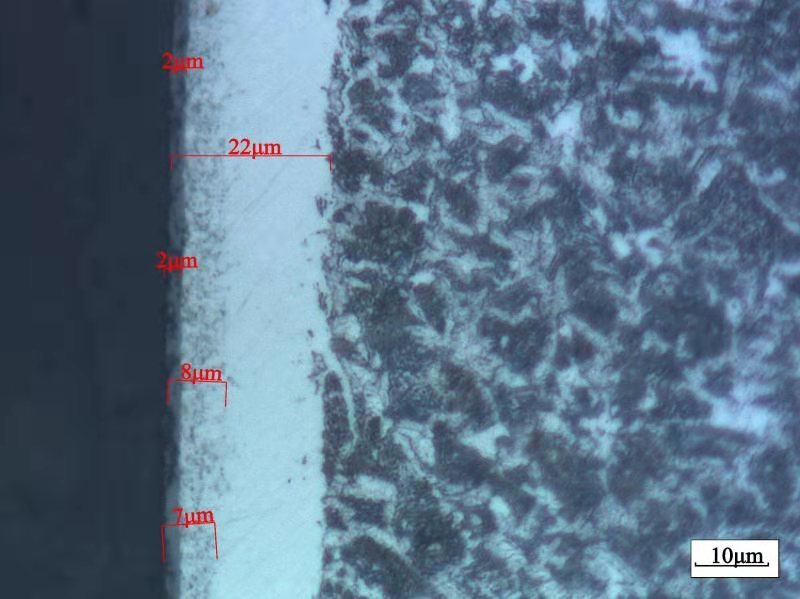

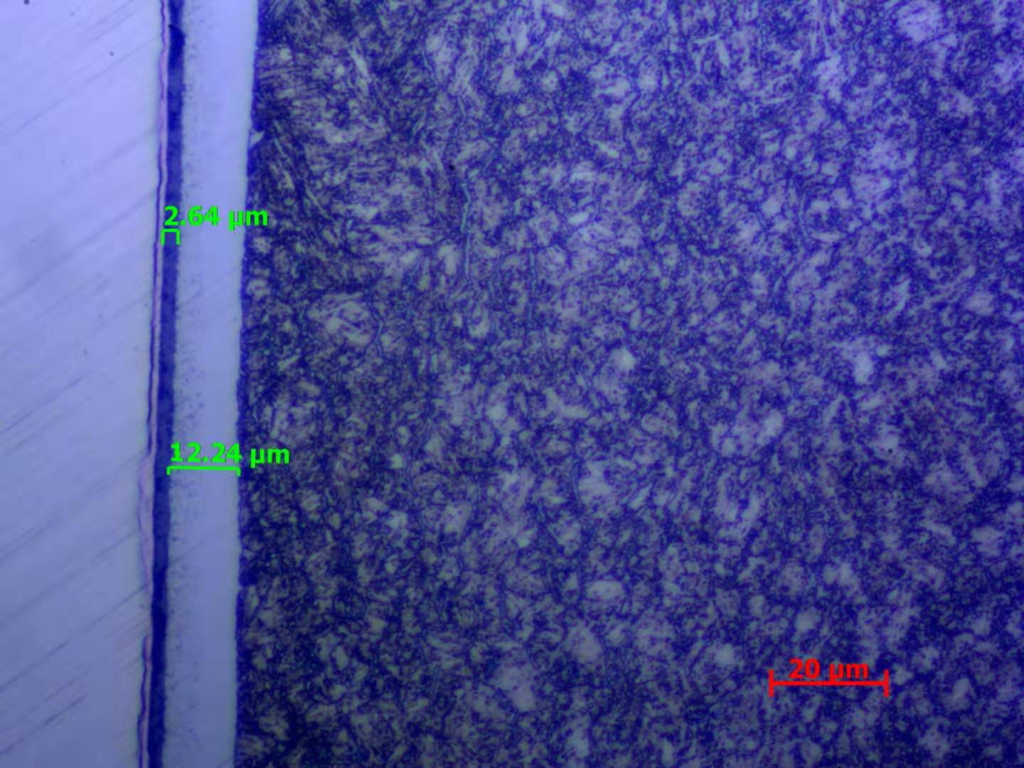

经氮碳氧复合处理后的零件表面依次为氧化层、化合物层、渗氮扩散层及基体组织。氧化层及化合物层主要可抵御大气的腐蚀,在标准盐雾试验条件下,其抗锈蚀能力保证不低于240小时,部分可达1000小时以上。另外化合物及渗氮扩散层可确保零件表面的高硬度,使其具备耐磨性。

NCO compound treatment furnace: 1. All kinds of steel, cast iron parts are surface NCO compound treatment, being widely applied in automobile parts, molds, oil drilling tools, kitchenware and other areas with higher requirements for abrasion and corrosion resistance. 2. One of replacements of the surface chromium plating, QPQ and other serious polluting process technologies.